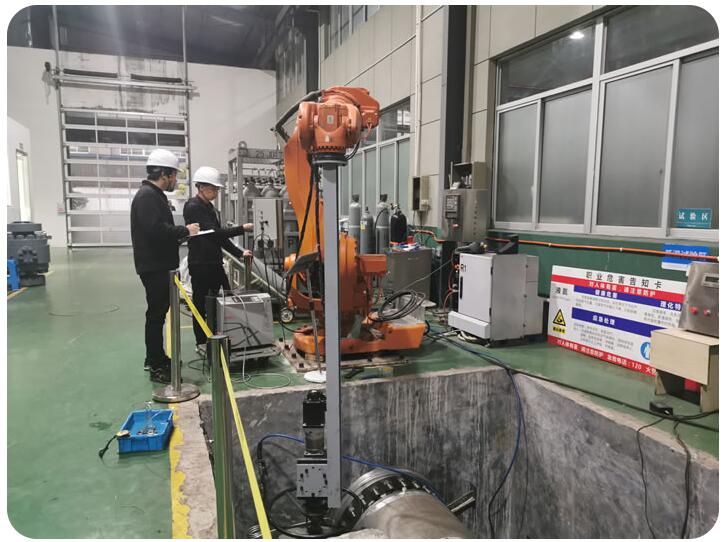

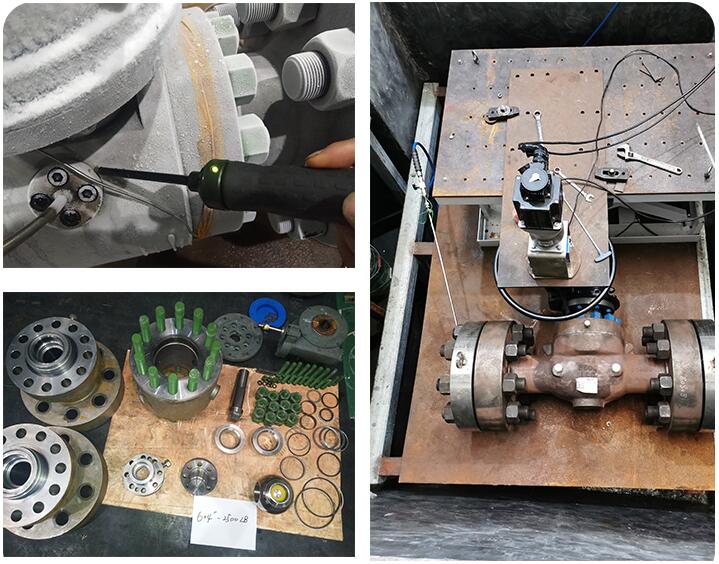

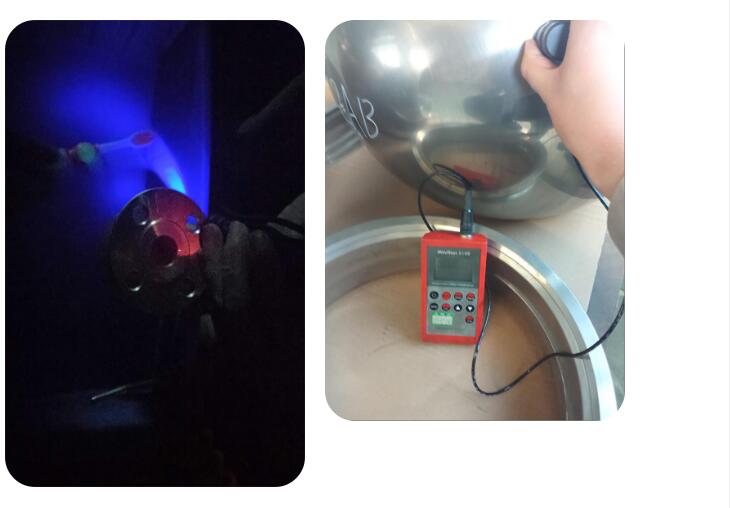

"Continuous improvement and pursuit of zero defects" is the quality policy and goal of FLOWSERVES (FZV) . We set up an internal quality assurance system and implement comprehensive and whole-process quality management to meet international and domestic standards and customer requirements. Flowserve has an advanced testing center, which can independently complete all the tests and tests from the product prototype test certification to the final product delivery inspection. These inspection, inspection include: ray detection, penetrant inspection, magnetic particle inspection, ultrasonic flaw detection, spectral analysis, material identification (PMI), microstructure test, all kinds of mechanical properties test, fire test, low temperature test, high temperature test, vacuum test, leak test, high pressure gas test, fluid dynamic test, the product life test, and the conventional water pressure experiment, and a series of valves. FLOWSERVES (FZV) has set up its own casting factory to ensure the quality of the billets. In addition,flowserve actively implemented six sigma management, implemented the "zero defect" project within the company, and achieved continuous improvement of process control and management ability through advanced data statistical analysis.

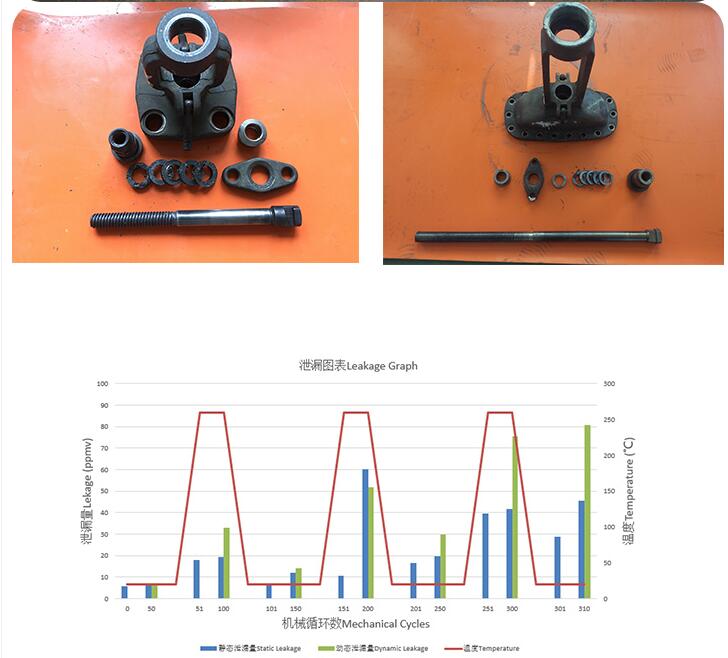

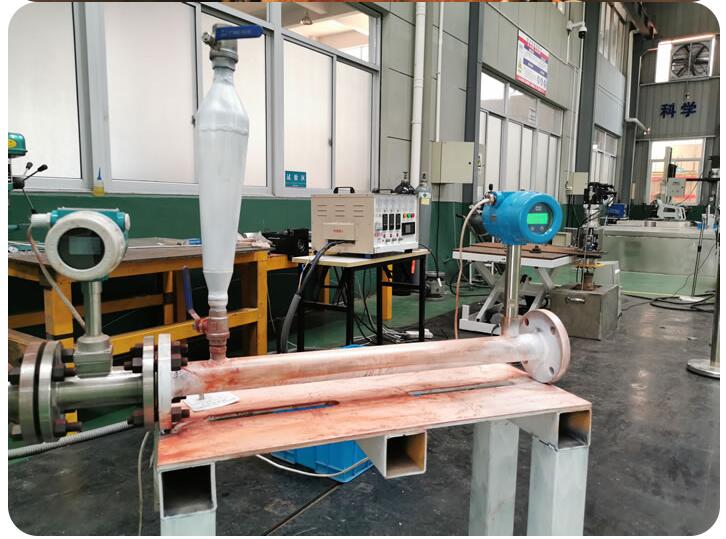

Testing of Process Valve Packing for Fugitive Emissions

API622-API624 Test

Fugitive Emissions:ISO 15848 VS.TA-Luft

Fugitive Emissions:ISO 15848 VS.TA-Luft

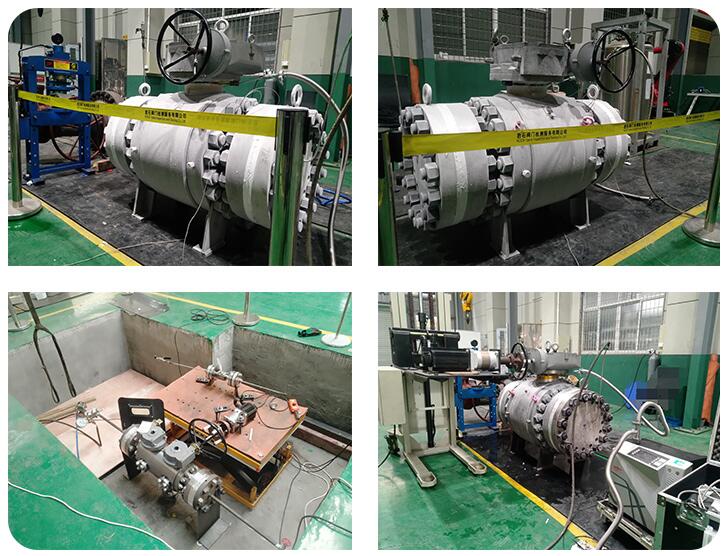

API641 Test

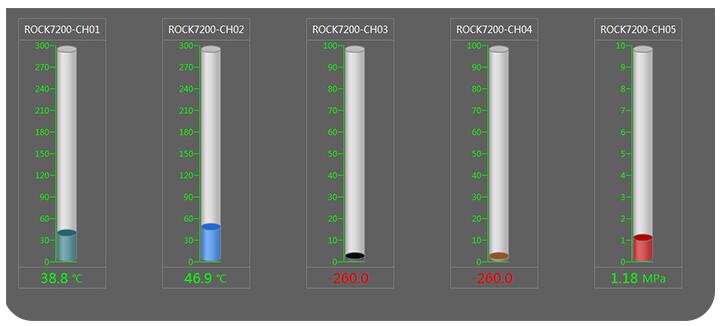

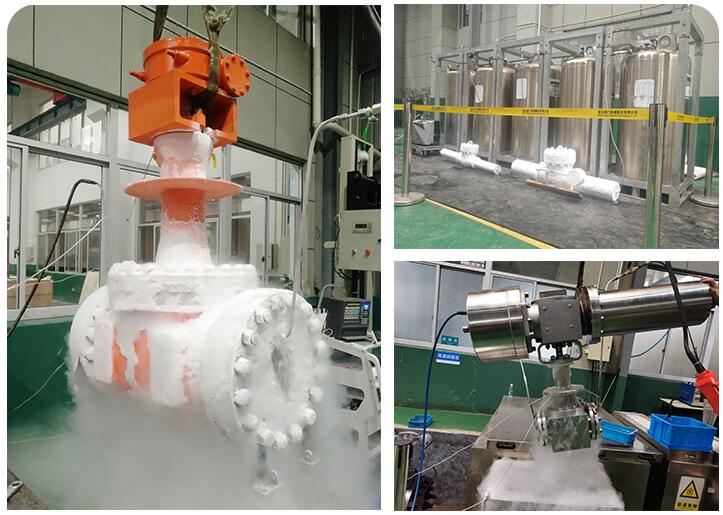

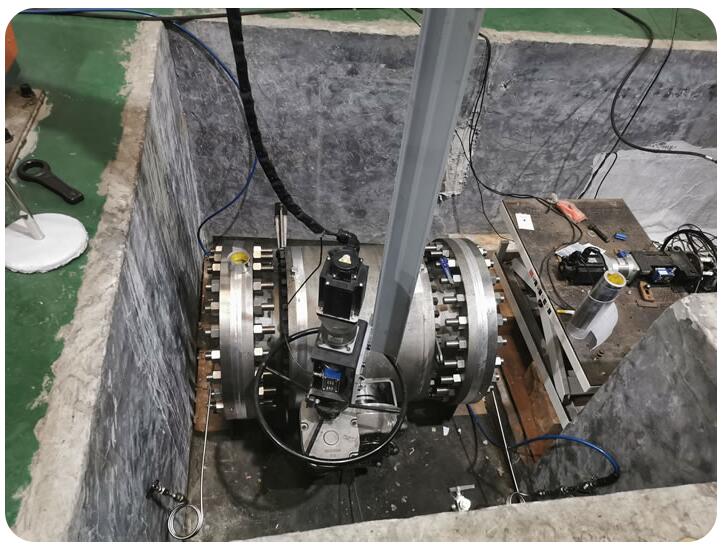

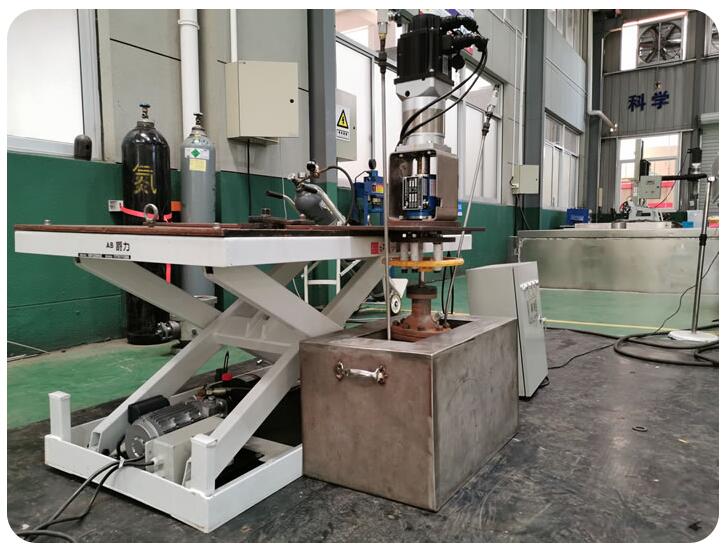

Cryogenic Test of Valves

Industry Valve Techonlogy Requirements(TAT)and Technical Specification MESC SPE 77-300

Test according to Gas Industry GI S/V7-1:200 7 Standard

ASTM E21-13 High temperature Test

Vacuum Technoogy-Valve-Leakage ISO27895

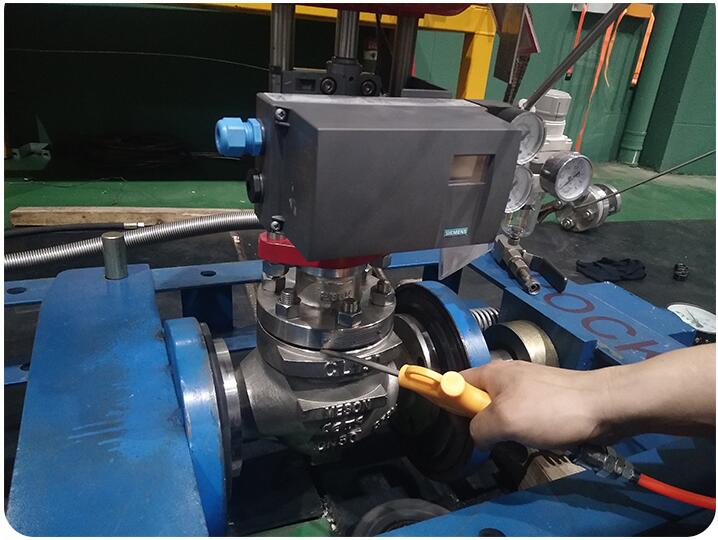

阀门性能诊断试验

阀门和管件第三方检验服务

|

|

OnlineQQ

OnlineQQ